Types of Servo Motor

DC Servo Motor

AC Servo Motor

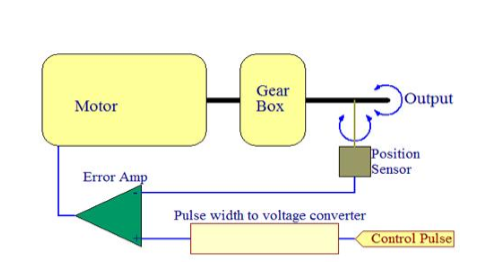

Basic working concept of servo motors

Applications

/* Name : main.c

* Purpose : Source code for SERVO MOTOR Interfacing with PIC18F4550.

* Author : Gemicates

* Date : 2017-06-22

* Website : www.gemicates.org

* Revision : None

*/

#include<xc.h> // Header file for PIC18F4550

#define _XTAL_FREQ 12000000 // 12MHZ

void delay_ms();

void delay_us();

unsigned int i;

void main()

{

CMCON = 0x07; // To turn off comparators

ADCON1 = 0x0F; // A/D control register

TRISC = 0x00; // PORTC as output

while(1) {

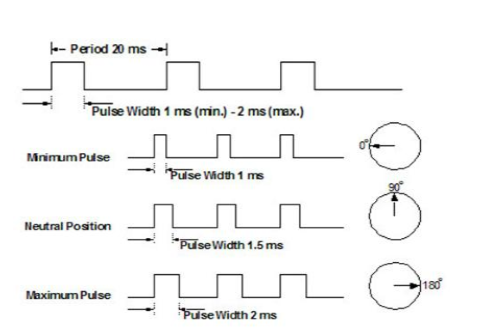

for(i=0;i<49;i++) // rotate to 0 degree

{

PORTCbits.RC0=1;

__delay_us(900);

PORTCbits.RC0=0;

__delay_us(19100);

}

__delay_ms(20); // delay for 0.02 sec

{

for(i=0;i<49;i++) // rotate to 45 degree

{

PORTCbits.RC0=1;

__delay_us(1250);

PORTCbits.RC0=0;

__delay_us(18750);

}

__delay_ms(20); // delay for 0.02 sec

{

for(i=0;i<49;i++) // rotate to 90 degree

{

PORTCbits.RC0=1;

__delay_us(1500);

PORTCbits.RC0=0;

__delay_us(18500);

}

__delay_ms(20); // delay for 0.02 sec

{

for(i=0;i<49;i++) // rotate to 1350 degree

{

PORTCbits.RC0=1;

__delay_us(1750);

PORTCbits.RC0=0;

__delay_us(18250);

}

__delay_ms(20); // delay for 0.02 sec

{

for(i=0;i<49;i++) // rotate to 180 degree

{

PORTCbits.RC0=1;

__delay_us(2000);

PORTCbits.RC0=0;

__delay_us(18000);

}

__delay_ms(20); // delay for 0.02 sec

}

}

}

}

}

}